Education

EDUCATION

Fundamentals of a Connected Job Site

Understanding the dynamics of a GPS-connected job site is paramount for organizations looking to enhance efficiency, safety, and overall project management within the construction, and heavy equipment communities.

Leveraging the power of GPS technology to monitor, manage, and optimize the use of equipment in real-time is the biggest benefit for organizations ready to shift from traditional equipment management and move towards an adaptive proactive organization. Making this shift encompasses several core elements, including various connectivity options, integration with Original Equipment Manufacturer (OEM) data, On Road and Off-Road GPS devices, Enterprise Resource Planning (ERP) system integrations, and adherence to fundamental equipment management practices.

Connectivity Options in a

GPS Connected Job Site

A well-integrated GPS-connected job site may employ various types of connectivity to ensure seamless communication between equipment, the job site, and office support teams. These include:

Cellular Networks:

Utilize existing cellular networks to provide wide-area connectivity. Most suitable for areas with reliable mobile service. In some regions cellular networks are not the most reliable. In these situations, ensure that your GPS partner has built in redundancies. As an example, recently we had a client that noticed a device had not reported in the last few hours and expected that it was due to a lack of connectivity. Because Gauge understood the use case, both the hardware and software was built with this situation in mind. All the historical data from the asset back fed into the system when it came back into coverage range. Not all devices are created equally.

Wi-Fi and WiMAX:

Offer local area connectivity, ideal for job sites that are more compact and where equipment does not travel far.

Satellite Communications:

Best for remote areas where cellular or Wi-Fi connectivity is unreliable.

The choice among these connectivity options would depend on the specific needs of the job site, including size, location, and the nature of the tasks being performed.

Tailored solutions for your fleet

Near Field Communications (NFC) and Bluetooth:

These are 2 low-cost solutions that provide connectivity within short range. While these low-cost solutions are very attractive and should evolve with time, the problems that they solve as sometimes very limited and dependent on other devices’ accuracy and/or proximity of detection.

The functionality of all of these devices is intricately tied to the nearby routing device. One example of this is a Bluetooth transponder that communicates with a cell phone that is 200 yards away, that cell phone is leveraging it’s GPS location as the location of the device which can be significantly different than the location of the BT device.

On-Road and Off-Road GPS Devices

Depending on your situation leveraging the OEM feed for equipment that comes with a factory fit solution may be the best solution, however there are several situations where the OEM solution does not meet the clients’ requirements, or the asset does not have a device currently available.

In these situations, there are several (maybe too many) options for customers to consider. These options include daily location, daily hours and location, battery options, direct OEM ruggedized boxes, to low-cost low fidelity solutions.

When selecting a provider for these boxes there are several considerations. Upfront cost, and contract duration are two items that most people focus on, however we have learned that the durability, reliability, integration options, professional service, and support staff are the most critical things to consider when finding a GPS partner.

Brands and OEM Data Integrations

Several leading brands offer GPS tracking and management solutions, like Caterpillar's VisionLink, John Deere JD Link, Komatsu's KOMTRAX, and Volvo's CareTrack.

These systems provide insights into equipment health, usage, and geolocation. Integrating with OEM data allows for real-time access to valuable metrics directly from the equipment's built-in sensors, enhancing decision-making regarding maintenance, deployment, and procurement.

Ensure that you understand who owns the data and what access you have to leverage and or integrate that data into your computerized maintenance management system (CMMS), and/or ERP.

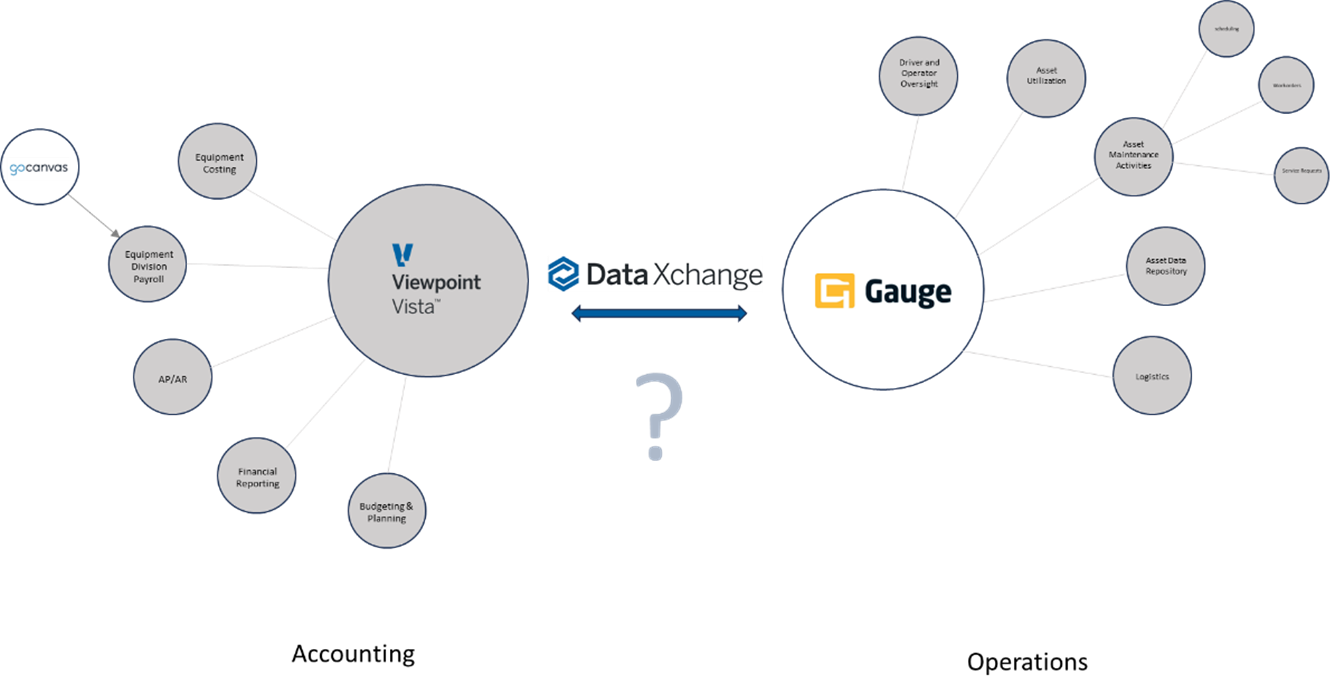

ERP Integrations

When your business systems “talk” with your asset tracking platform, you and your team achieve unprecedented efficiency! Enter data once and sync it across the company for powerful decision-making.

Integrating GPS data with an organization's ERP system streamlines operations by connecting real-time field data with back-office functions such as inventory management, procurement, and finance. ERP integrations facilitate a holistic view of the organization's operations, making it easier to track project costs, manage payroll based on actual equipment usage, and ensure compliance with safety and operational standards. For several smaller to medium sized organizations this is not a critical element when they are first selecting a partner or connecting their fleet, however it is an important consideration for companies that intend to adapt their organization as it grows.

HUMAN CONNECTIVITY

One critical aspect of connectivity that is typically lost or forgotten about is human connectivity and the smart phone or manual paperwork that is being created. Too often, fancy and cool try to add a solution where there is no problem. Keep this in mind when building out your connected company. There are people in the field and in the office that need to be considered and how they currently do business.

Ask yourself if there is a way to limit change and leverage things that are already in place. One example: If people are already using paper and pencil to rent machines from a dealer. There is a way to have that rental house send a pdf copy to an automated email that logs and read the pdf. That enables the data to kick off workflow automation for the invoicing and accounts payable without any change in the field. Or collecting “used” lock out tag out indicators at the end of every shift to manage fleet utilization and reliability.

Find a partner that can help you understand your business to make these ideas a reality.

FOUR FUNDAMENTALS OF EQUIPMENT MANAGEMENT

Optimal management of equipment on a GPS-connected job site centers around four fundamental principles:

1

Understand Your Cost

Detailed insights into the operational and maintenance costs of each piece of equipment enable more informed financial decision-making.

2

Manage Fleet Age

Keeping track of the age profile of your fleet helps in planning for replacements and avoiding the increase in maintenance costs associated with older equipment.

3

Ensure Reliability

Regularly monitoring equipment health and performance data contributes to preventing breakdowns and minimizing downtime.

4

Maximize Utilization

Understanding how equipment is being used on the site ensures resources are not lying idle or being underutilized, leading to cost savings and project efficiency.

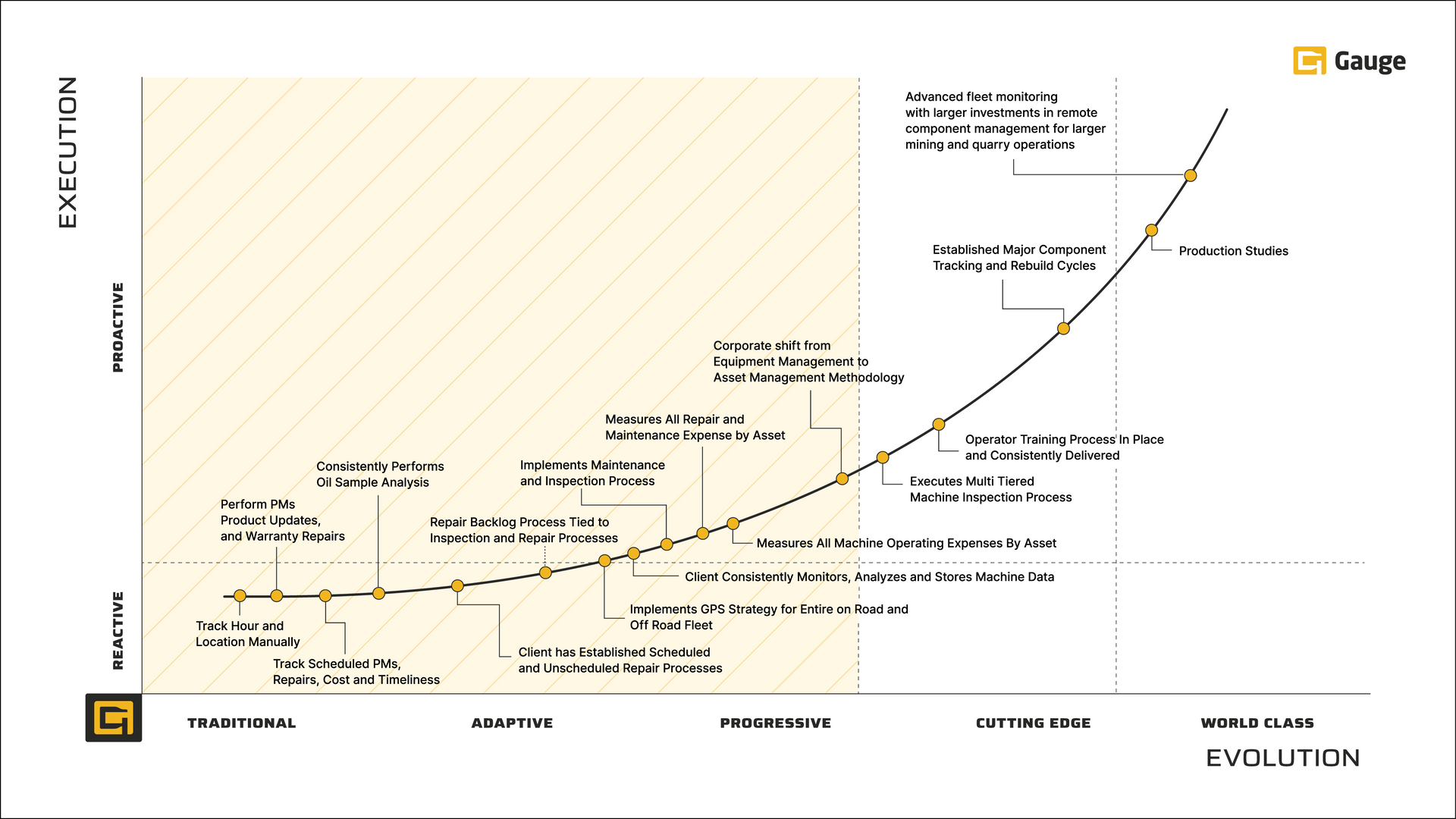

EQUIPMENT MANAGEMENT MATURITY CURVE

As organizations and their business partners look to enhance their use of GPS-connected job sites, they must evaluate their position on the equipment management maturity curve.

This evolutionary process typically moves from the initial stages of manual tracking and reactive maintenance to more advanced stages characterized by predictive analytics and fully integrated systems. Progressing along this curve requires a strategic approach to technology adoption, staff training, and process reengineering, aiming for an optimized state where data-driven decision-making ensures maximum efficiency and equipment ROI.

CONNECTIVITY AND MAINTENANCE:

AEM Association of Equipment Manufactures, AED Associate or Equipment Dealers, IEDA Independent Equipment Dealers Association, and AEMP Association of Equipment Management Professionals all recommend that customers leverage a CMMS to help them manage their fleets maintenance. It is important to ensure that the company building the CMMS has 4 critical features.

Hardware

Built to the highest industrial standard (IP69K) and supported to ensure 99.5% uptime and local support with experts that understand your industry. Keep in mind that some of the products are on road devices repackaged as “construction ready".

Software

Industry specific software that was built with customers in our industry for customers in our industry.

Post Purchase Support

After the sales team is long gone how does your provider ensure uptime and minimum service level agreements? Updates, Outages, Contract terms, and Technical Support.

Industry Longevity

Ensure that your peers provide a positive review and recommend these products. What happens if the company can’t support you long-term? How long have they been in business and how many customers have they retained through those years?

Data Integration

Data Integration for Telematics and Business Information: Even if you are not ready to integrate your business system today, ensure that the data from your OEM integrations, OEM business partners, and your business system can integrate within your CMMS.

Benefits of Connectivity

Connectivity is the backbone to moving up the equipment management maturity curve.

Gauge Telematics has focused on helping our core customer segment focus on the most cost effective and impactful solutions that enable them to get to their desired goal. That might just be understanding hours and location, or it could involve entering the progressive space.

Conclusion

Adopting a GPS-connected job site approach brings substantial benefits across various dimensions of equipment management. By focusing on connectivity options, leveraging integrations with OEM data and ERP systems, and adhering to the fundamentals of equipment management, organizations can significantly enhance operational efficiencies. Furthermore, understanding one's position on the equipment management maturity curve is crucial for strategic planning and continuous improvement, ensuring that investments in technology and processes yield the desired competitive advantage.