Simplifying Heavy Equipment Maintenance with Gauge Maintenance 2.0

Simplifying Heavy Equipment Maintenance with Gauge Maintenance 2.0

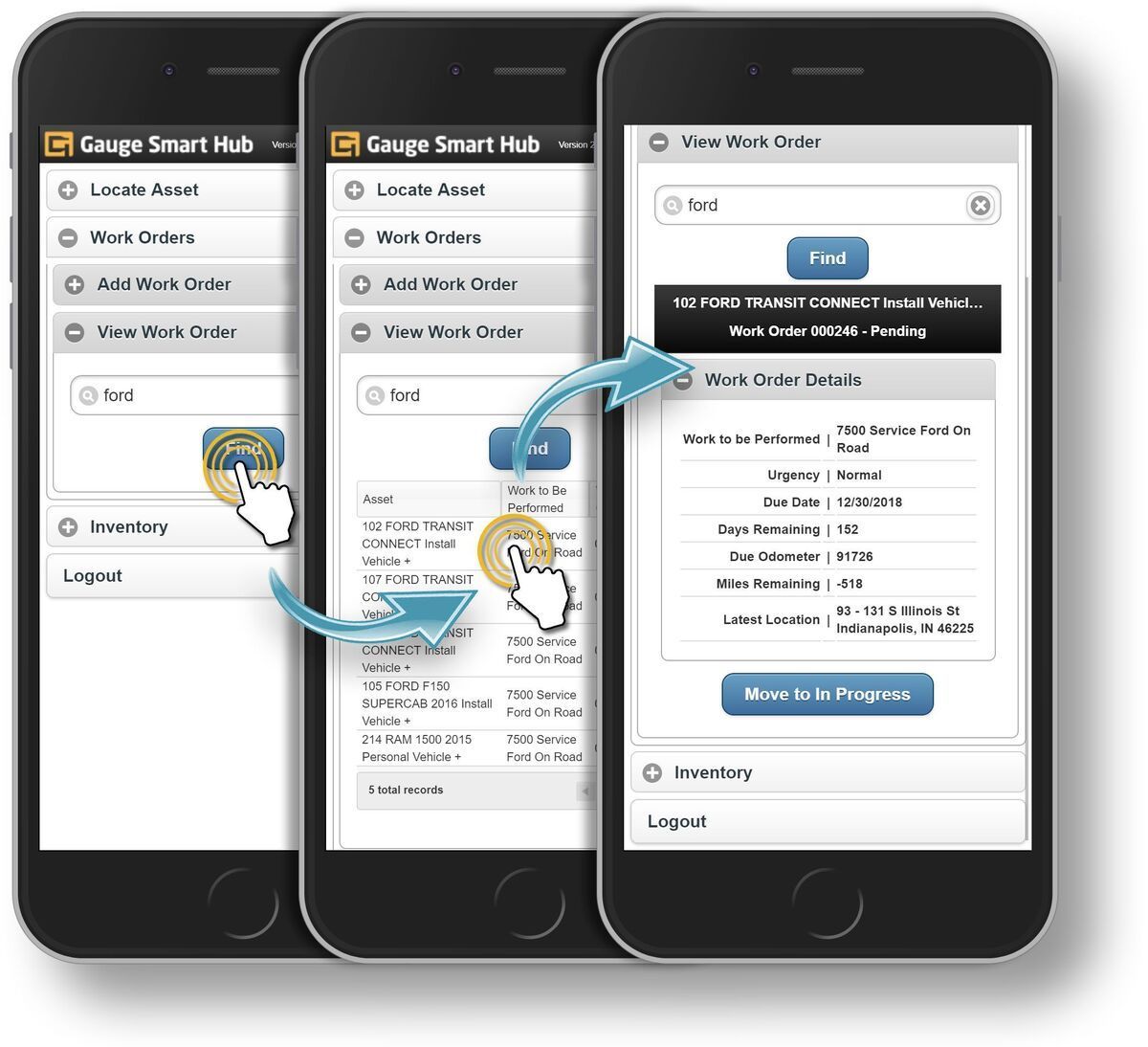

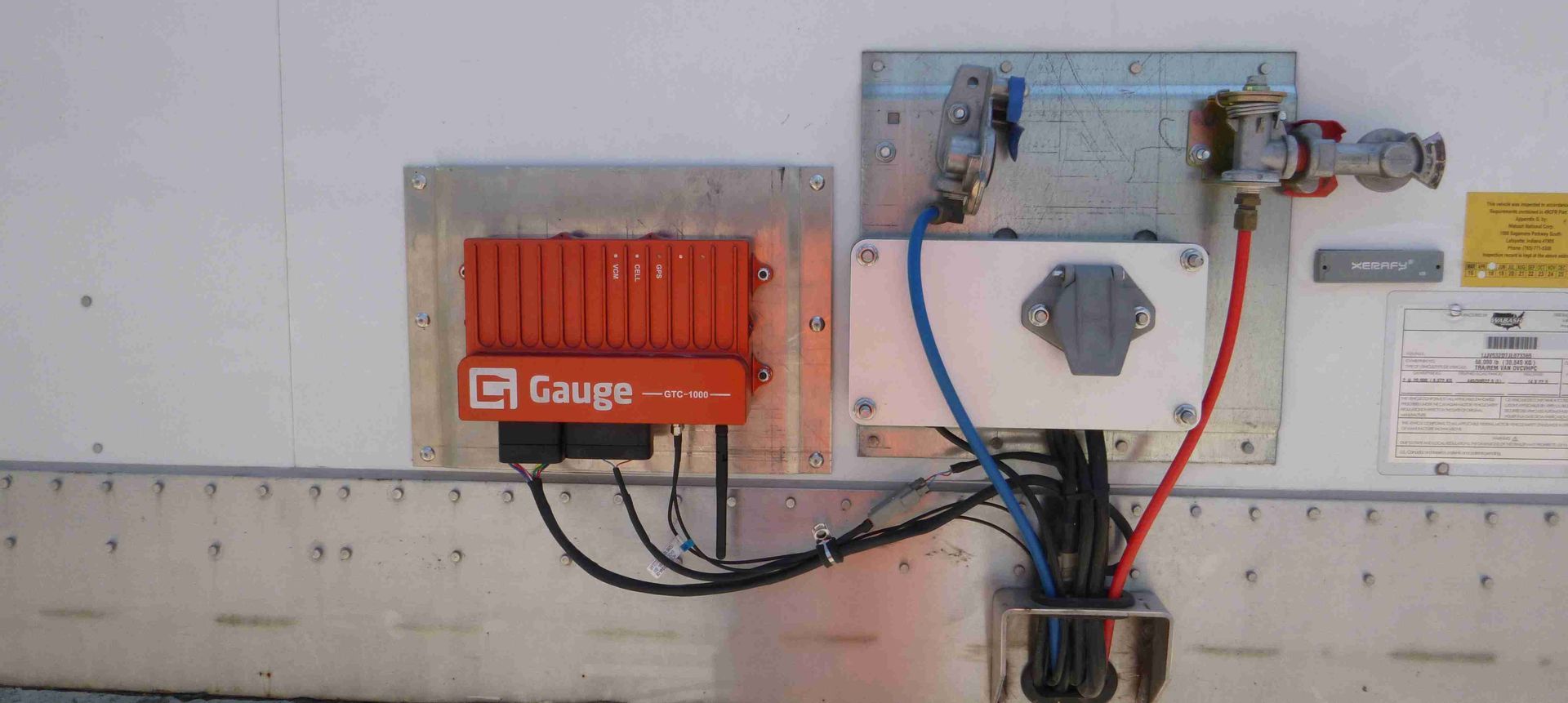

Managing heavy equipment and ensuring it stays in optimal condition requires careful planning and precise timing, especially when dealing with maintenance intervals. For fleet managers and maintenance teams, scheduling regular service based on hours of use is essential, but the complexities of real-world logistics often introduce challenges. This is where Gauge Maintenance 2.0 comes into play, reducing these complexities to help businesses focus on their operations rather than maintenance headaches.

The Reality of Maintenance Intervals

When new equipment is purchased, maintenance intervals are typically set in blocks based on usage hours—500 hours, 1000 hours, and 2000 hours are common thresholds. On paper, these intervals are easy to track and schedule. However, once the machine is in the field, reality sets in. Maintenance might be due at 500 hours, and actually be completed at 625 hours, or some other in-between time, making scheduling a balancing act. This is where the real question arises: do you shift everything to 625 hours, effectively extending the intervals and potentially losing out on the 125 hours of maintenance, or do you keep everything on track and deal with the logistics of misaligned schedules?

As maintenance intervals stretch into the 2000-hour and 6000-hour range, the challenge only grows. Shifting intervals based on real-world usage means constant adjustments, potentially affecting the efficiency and performance of your fleet. With Gauge Maintenance 2.0, you don’t have to rely on guessing or struggling with misaligned service times. Our platform offers complete visibility into these scheduling complexities, allowing you to move maintenance intervals forward or delay them as needed, ensuring that your fleet operates efficiently without compromising on service.

Automated Reporting for Easier Fleet Management

One of the key benefits of Gauge Maintenance 2.0 is automated reporting. With this tool, fleet managers can access daily, weekly, or monthly reports to track each asset’s maintenance status, making it easier to stay ahead of service needs. Whether you’re managing a single asset or an entire fleet, this level of automation helps streamline your processes and reduce the administrative burden, allowing you to focus more on the other tasks that drive your business forward.

The Used Equipment Dilemma

What about when you purchase a used machine? It's exciting, yes, but it also comes with its own set of uncertainties. You may not know the full maintenance history of the machine, which can make it difficult to predict when the next service will be due. Industry experts often recommend performing a 2000-hour service on a used machine and then treating that as the start of a “new maintenance cycle”. Gauge Maintenance 2.0 aligns perfectly with this approach, offering the flexibility to handle such situations with ease.

By allowing you to input service records, parts, and labor costs, Gauge helps you build a complete maintenance history for each asset, even if the machine is pre-owned. This data is crucial for establishing a baseline to forecast the asset’s lifecycle and make informed decisions. With these insights, you can define your lowest cost per hour (CPH) and predict future maintenance needs with accuracy, ensuring that every asset in your fleet is running at its best.

Accurate Lifecycle Forecasting

The true value of Gauge Maintenance 2.0 lies in its ability to forecast the lifecycle of your equipment, both at the fleet level and for individual assets. By gathering accurate data about service history, parts usage, and labor costs, you can gain a deep understanding of each machine’s needs. This enables better long-term planning, cost management, and ensures that your fleet stays productive and reliable for as long as possible.

Conclusion

Heavy equipment maintenance is full of challenges, from the complexities of scheduling service at odd intervals to managing the unknowns when buying used machines. But with Gauge Maintenance 2.0, these challenges are simplified. Whether you’re managing new equipment or used machinery, Gauge helps you navigate the complexities of maintenance scheduling, track the health of your assets, and make data-driven decisions that improve the bottom line. Say goodbye to maintenance headaches and hello to smoother, more efficient fleet management with Gauge.