Gauge Launches Asset Management Software for Public Health

Marion County Public Health Dept. in Indianapolis

SMART HUB LABS IMPROVES MANAGEMENT OF ASSETS

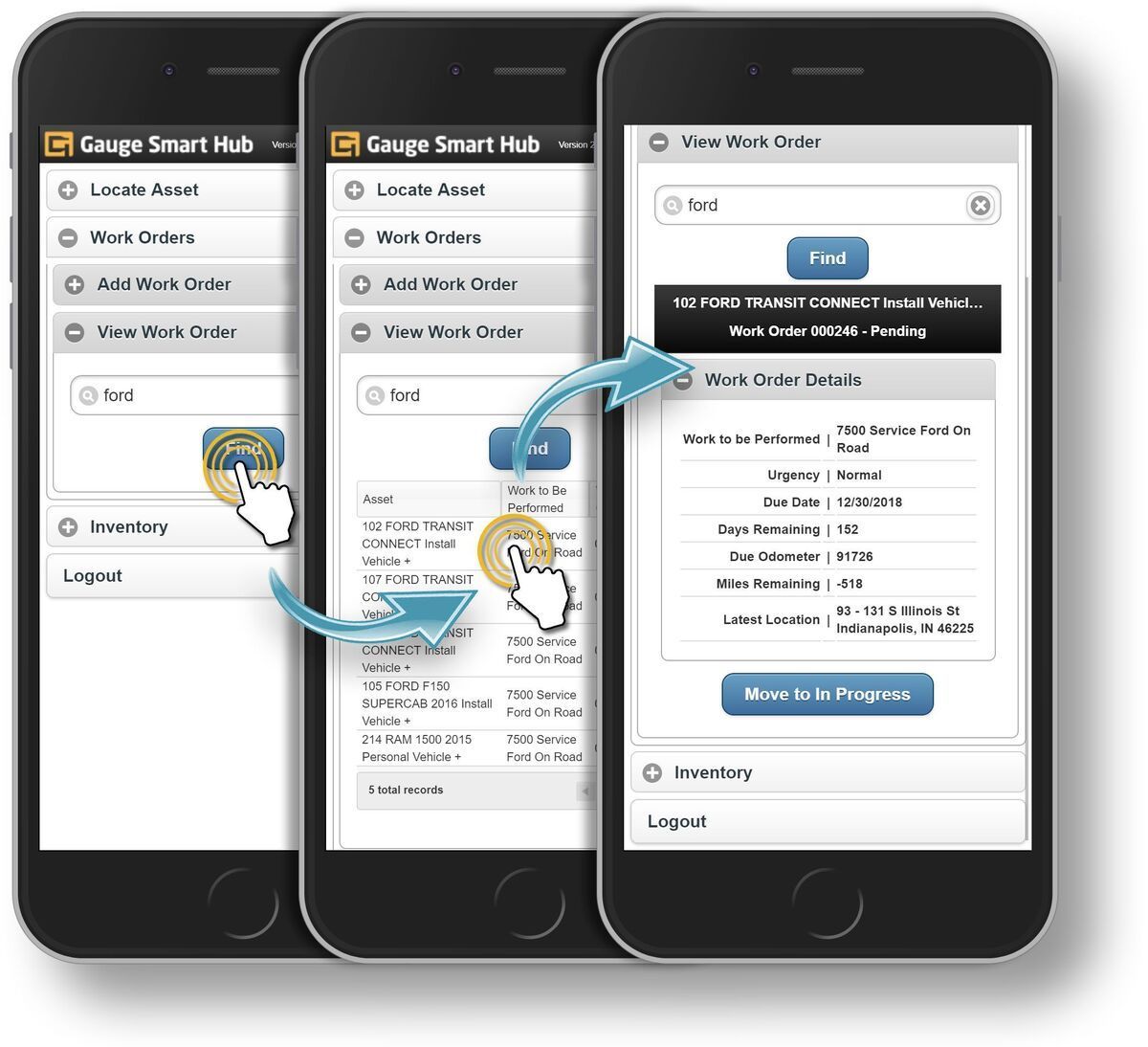

Gauge announced today that it has launched Smart Hub Labs software for public health and other types of laboratories. The telematics provider has refined and adapted its web-based asset management tool to digitally track labs' physical assets, forecast maintenance and gather information for audits.

“With Smart Hub Labs' digital management, data collection and delivery, you gain immediate access to the data you need, which allows your lab to operate more efficiently.” explained Gauge CEO Mike Paredes.

Smart Hub Labs assists with preventive maintenance, calibration schedules and warranty renewals. Regularly scheduled maintenance ensures that lab operations do not experience interruptions, resulting in cost savings. The software also saves time when accessing data for audit, satisfying inspectors with the simplified process and elimination of follow-up details.

Gauge is partnering with J Michael Consulting LLC (JMC) to make its software available to labs – JMC is an authorized value-added reseller of Smart Hub Labs. JMC's Dr. Bonny Van Lewis, a recognized expert in public health and clinical labs, worked with Gauge's Smart Hub when she served as the lab director at the Marion County Public Health Department in Indianapolis.

"As part of an overall Lean improvement plan in the lab, the adoption of Gauge's Smart Hub allowed us to reduce time and effort spent on asset management," she said. "In most cases, we were able to respond to asset information requests in less than a day, with the process of reporting requiring less than 10 minutes. This freed lab staff to work on other improvement projects."

Van Lewis said that five years later, the asset management tool is an integral part of Marion County's laboratory operations.

ABOUT J MICHAEL CONSULTING In August of 2011, J Michael Consulting (JMC) was founded with a focus on public health informatics. The JMC team is comprised of staff with expertise in a wide range of scientific and technical fields. JMC areas of expertise include Laboratory Informatics, Data Standards and Interoperability and Project and Program Management. Scientific experience among JMC staff include hands on experience at both state and federal public health laboratories, specifically serological diagnostic assays, virus characterization and molecular assay performance design and implementation. In addition to bench laboratory experience, JMC team members also have a strong background in public health case reporting, electronic laboratory report, quality management, standard implementation and outbreak notification. Most importantly however, the staff at JMC are experts in informatics. Staff have worked on diverse informatics projects from internal small-scale implementations to large, cross-agency national programs. Roles held include the entire breadth of informatics program support from software selection and implementation, shoulder-to-shoulder business analysis, training and project management.

JMC staff share the core values of Integrity, Respect, Service and Fun and bring these characteristics with them to their projects. They enjoy serving their communities through steadfast support of the missions of public health, implementing projects side-by-side with their clients striving to make a difference while building long-lasting relationships. JMC puts the needs of the client and the team first and takes pride in providing the tools needed to make the client successful. With over a half a century of combined experience, the JMC team can meet the needs of a wide client base with a strong combination of skill and innovation.

ABOUT GAUGE Gauge Telematics is a leading provider of real-time asset tracking for improved equipment utilization, fleet management and process efficiency. Gauge enables fleet operators to organize, track and maintain assets of all types in a secure, central location. Through its robust asset management platform, Gauge Smart Hub, Gauge empowers users to rapidly gain control of fleet data and maintenance to achieve company-wide statistical reporting. Located in Indianapolis, Ind., Gauge is trusted by companies around the world to deliver smart, reliable tracking solutions that drive smart decision making for business growth.